Stainless Steel Pipe For Mechanical

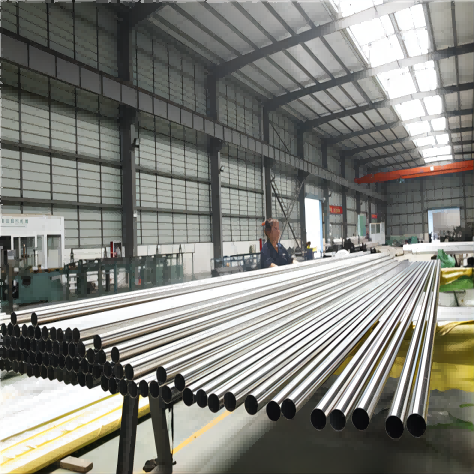

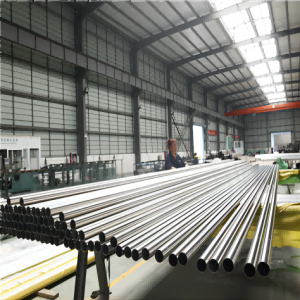

Introduction of Stainless Steel Pipe For Mechanical Structure:

Stainless steel pipe for mechanical structure is a stainless steel pipe that needs to be assembled to the machine in the application and needs to bear a certain weight. Its working environment is relatively harsh, and its parts are easy to be corroded. Therefore, the implementation standard has relevant requirements for tube making methods, dimensional deviations and mechanical properties

DIMENSION TOLERANCE TABLE OF ROUND TUBING:

| Standard | Outside Diameter(mm) | Thicknes(mm) | Outside Diameter Tolerance(mm) | Thickness Tolerance (mm) | Length Tolerance(mm) |

| ASTM A554 | ≤12.7 | 0.51~1.24 | ±0.10 | ±10.00%T(±10.00%of nominal wall thickness) |

+4.08 -0 |

| >12.7~25.4 | 0.51~1.65 | ±0.13 | |||

| >1.65~3.4 | ±0.25 | ||||

| >25.4~38.1 | 0.64~1.65 | ±0.20 | |||

| >1.65~3.40 | ±0.25 | ||||

| >38.1~50.8 | 0.64~1.24 | ±0.25 | |||

| >1.24~2.11 | ±0.28 | ||||

| >50.8~63.5 | >2.11~3.78 | ±0.30 | |||

| 0.81~1.65 | ±0.30 | ||||

| >1.65~2.77 | ±0.33 | ||||

| >63.5~88.9 | >2.77~4.19 | ±0.36 | |||

| 0.81~4.19 | ±0.36 | ||||

| >88.9~127.0 | 0.89~4.19 | ±0.51 | |||

| >4.19 | ±0.64 | ||||

| >127.0~190.5 | 1.24~6.35 | ±0.64 | |||

| >6.35 | ±0.76 | ||||

| GB/T 12770 | <25 | ±0.15 | Cold Rolled≤0.50 ±0.05 >0.50~1.00±0.11 >1.00~2.00±0.17 >2.00~3.00±7.00%S >3.00 ±10.00%SHot Rolled ±10.00%S |

+20.00 -0 |

|

| ≥25~40 | ±0.18 | ||||

| ≥40~50 | ±0.20 | ||||

| ≥50~60 | ±0.23 | ||||

| ≥60~70 | ±0.30 | ||||

| ≥70~80 | ±0.30 | ||||

| ≥80~90 | ±0.30 | ||||

| ≥90~100 | ±0.40 | ||||

| ≥100~200 | ±0.50%D | ||||

| ≥200 | To Be Agreed | ||||

| JIS G3446 | <50 | ±0.25 | <3.00 ±0.30 | +50 -0 |

|

| ≥50 | ±0.5% | 23.00 ±10.00% |

ASTM A554 Steel Tubing Chemical Composition

| ASTM A554 TUBING GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| ASTM A554 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| ASTM A554 L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| ASTM A554 316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| ASTM A554 316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

A554 Steel Tubing Mechanical Properties

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min.º F(º C) | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| ASTM A554 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| ASTM A554 L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| ASME SA554 316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| ASTM A554 316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

ASTM A554 Steel Tube Weight Chart

DIMENSIONS OF ASTM A554 WELDED MECHANICAL TUBING OUTSIDE AND INSIDE DIAMETER OR WALL

| OD Size, in. (mm) | OD, ±in. | mm | ID, ±in. | mm |

| Up to 3⁄32 (2.4), excl | 0.001 | 0.03 | 0.001 | 0.03 |

| 3⁄32 to 3⁄16 (2.4 to 4.8), excl | 0.0015 | 0.038 | 0.0015 | 0.038 |

| 3⁄16 to 1⁄2 (4.8 to 12.7), excl | 0.003 | 0.08 | 0.005 | 0.13 |

| 1⁄2 to 1 (12.7 to 25.4), excl | 0.004 | 0.1 | 0.006 | 0.15 |

| 1 to 11⁄2 (25.4 to 38.1),excl | 0.005 | 0.13 | 0.007 | 0.18 |

| 1 1⁄2 to 2 (38.1 to 50.8),excl | 0.006 | 0.15 | 0.008 | 0.2 |

| 2 to 2 1⁄2 (50.8 to 63.5),excl | 0.007 | 0.18 | 0.01 | 0.25 |

| 2 1⁄2 to 3 1⁄2 (63.5 to 88.9),excl | 0.01 | 0.25 | 0.014 | 0.36 |

| 3 1⁄2 to 5 (88.9 to 127.0),incl | 0.015 | 0.38 | 0.02 | 0.51 |

| Over 5 to 16 (127.0 to 406.4), incl | 0.00125 in./in. or mm/mm of cir-cumference | 0.0013 in./in. or mm/mm of cir-cumference |

Application of Stainless Steel Pipe For Mechanical Structure:

These ASME SA 554 SS 316 Mechanical Tubing are demanded for diverse structural applications. They are used in areas like petroleum, power, papermaking, chemical, aviation, boiler heat-exchanger and others. The most well known application stainless steels are probably for cutlery and kitchenware. Probably the most demanding industries that use stainless steels are the chemical, processing and oil & gas industries have created a large market for stainless tanks, pipes, pumps and valves as well. Stainless steels and other corrosion resistant alloys are extensively used in the power generation industry to combat corrosion, particularly at elevated temperatures. Also large amounts of stainless steel are used in food production and storage.